Big Capacity Automatic Yeast Donut Making Production Line For Sale

Big Capacity Automatic Yeast Donut Making Production Lineis improved on the basis of our company in Malaysia and the United States on imports of donut equipment. All-stainless steel, in full compliance with food hygiene requirements.

We're here to help:

Easy ways to get the answers you need.

- 0086 155 1559 7212

- serena@machinehall.com

- 0086 155 1559 7212

Application

It is mainly used for moulding, blanking, frying and discharging donuts.

Main Feature

The machine is capable of producing a variety of mini donuts integrated equipment.

Features

Introduction:

Big Capacity Automatic Yeast Donut Making Production Line is improved on the basis of our company in Malaysia and the United States on imports of donut equipment. All-stainless steel, in full compliance with food hygiene requirements. Siemens sensors, electrical control sensitive, good fried efficiency, is your choice for production of high profile donuts.

Characteristics

Characteristics

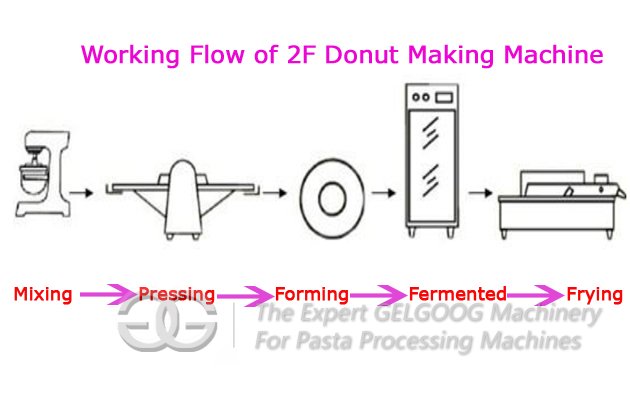

The donut making machine is capable of producing a variety of mini donuts integrated equipment, the replacement of mold production of various types of donuts. Complete production line manufactured according to GMP standards, standardized production processes, less human factors, product quality and stability, in line with food hygiene requirements of GMP. This type of machine is designed specifically for deep-fried fermented donuts. Set automatic temperature control, auto-flip, auto-frying, pan automatically in one. Any shape can be deep-fried donuts and pasta food. Only one person will be able to complete all operations.

Advantage:

1. Stainless steel furnace, energy efficient heating appliances, automatic molding, automatic temperature control function, automatically turn the donut, using screw-type adjustable device, discharge port can be up and down arbitrarily according to the height of oil level. The size of donut can also be adjusted.

2. This machine use precise orbit devices, import motor, which maintaining equipment vibration in the smallest value.

3. Large hopper design, simple operation and high efficiency.

4. Installation is possible in a limited space.

5. Electric energy saving.Convenient cleaning after the operation.A low rate of breakdown.

Technical Data

| No. | Capacity | Describe | Quantity |

| 1 |

400pcs/h GGQ2F (table type ) |

Automatic feeding conveyor | 1 |

| Automatic frying machine | 1 | ||

| Automatic discharging conveyor | 1 | ||

| Special equipment table | 3 | ||

| Filter machine | 1 | ||

| 2 | Dough mat | 50 | |

| 3 | Draw bar | 5 | |

| 4 | Fermentation tray | 50 | |

| 5 | Dough mixer machine | 1 | |

| 6 | Sheeter | 1 | |

| 7 | Mould | 4 | |

| 8 | Fermentation room | 1 | |

| 9 | Chocolate insulation cylinder | 1 | |

| Note:The machines with red color are the corollary equipments, the buyers can choose them according to the requirements of themselves. | |||

FAQ

Q: What about the capacity of the donut making production line?

A: We have different modles, different capacities, 400 pcs/h, 800pcs/h, 1600pcs/h.

Q: What kinds of mould can i choose to form donut?

A: We can customize the shapes based on your demand.

Q: Can you change the voltage for me?

A: Yes, of course. We can change the voltage to suit your country's.

A: We have different modles, different capacities, 400 pcs/h, 800pcs/h, 1600pcs/h.

Q: What kinds of mould can i choose to form donut?

A: We can customize the shapes based on your demand.

Q: Can you change the voltage for me?

A: Yes, of course. We can change the voltage to suit your country's.